The engine has been removed from the machine. Now what? View the article below to build a low cost shipping stand that will prevent damage while in transit.

Materials needed;

2X 4X4X8 Pressure treated Posts (or equivalent). The PT posts seem to be the lowest cost

2X 2X4X8 Wood Studs

2X 1/2" Lag Bolts with Flat Washers

1X 40"X48" Heavy Duty Wood skid/pallet

3 1/2" Framing nails (interior type or exterior type) or deck screws.

When building the skid the goal is to support the front motor mounts and the bottom of the flywheel housing.

Step 1 - Cut 1X 4X4X8 in half. 2 equal pieces at 48" each.

Step 2 - Cut 1X 2X4X8 at 40" each. Quantity of 2.

Step 3. Determine the distance from the bottom of the oil pan to the bottom of the front motor mount. Usually between 12" to 14". Note add an extra 1" so the oil plug will not hit the top of the wood skid. Also, be aware of the oil filter position. Sometimes it comes in contact with the 4X4x48" support.

Step 4. Cut 2X - 4X4X8 pressure treated posts to the dimension found in step 3. Then cut 4X - 2X4X8 to the dimension found in step 3.

Step 5. Using remaining 4X4X8 pt posts, cut 6 triangular pieces at 45". This will add strength to the tower supports and the flywheel supports.

Step 6.Using remaining 2X4X8 studs, cut 2X 6" pieces and then drill a hole thru the center using a 3/4" wood spade bit.

Step 7. Determine the position of the front motor mount position on the skid. The goal is to make sure the engine is center on the skid. If the engine overhangs off of the skid you will get additional charges from the freight carrier. This could also cause damage in transit if any part of the engine is hanging off the skid.

Step 8. Nail or screw the 2X4X*40" studs to the 2X 4X4X48" posts. The 2X4X40" studs will eventually support the front motor mount brackets and the bottom of the flywheel housing.

Step 9. Turn bottom support over and position on the heavy duty wood skid so it is a square fit with no overhang. Nail or screw to the wood skid. Then nail the short 2X4X12 or 14 studs to each skid of the 4X4X48" post to create the tower for the front motor mounts. Place the 4X4X12 or 14 post in the center of the studs. Then nail or screw the triangle pieces to the front and rear of each tower strut.

Step 10. Please engine on skid. Using the 2X 6" 2X4 pieces, place on top of the motor mount and use the 1/2" lag screws with flat washers and anchor to the tower supports.

Step 11. With engine sitting level on the skid, determine the distance between the bottom of the flywheel housing and top of the 4X4 posts. Cut remaining 2X4 or 4X4 scrap pieces and then screw of nail across the 4X4 support posts. Using remaining 2 triangle pieces, screw or nail on each side of the flywheel housing. Then run banding material of the flywheel housing.

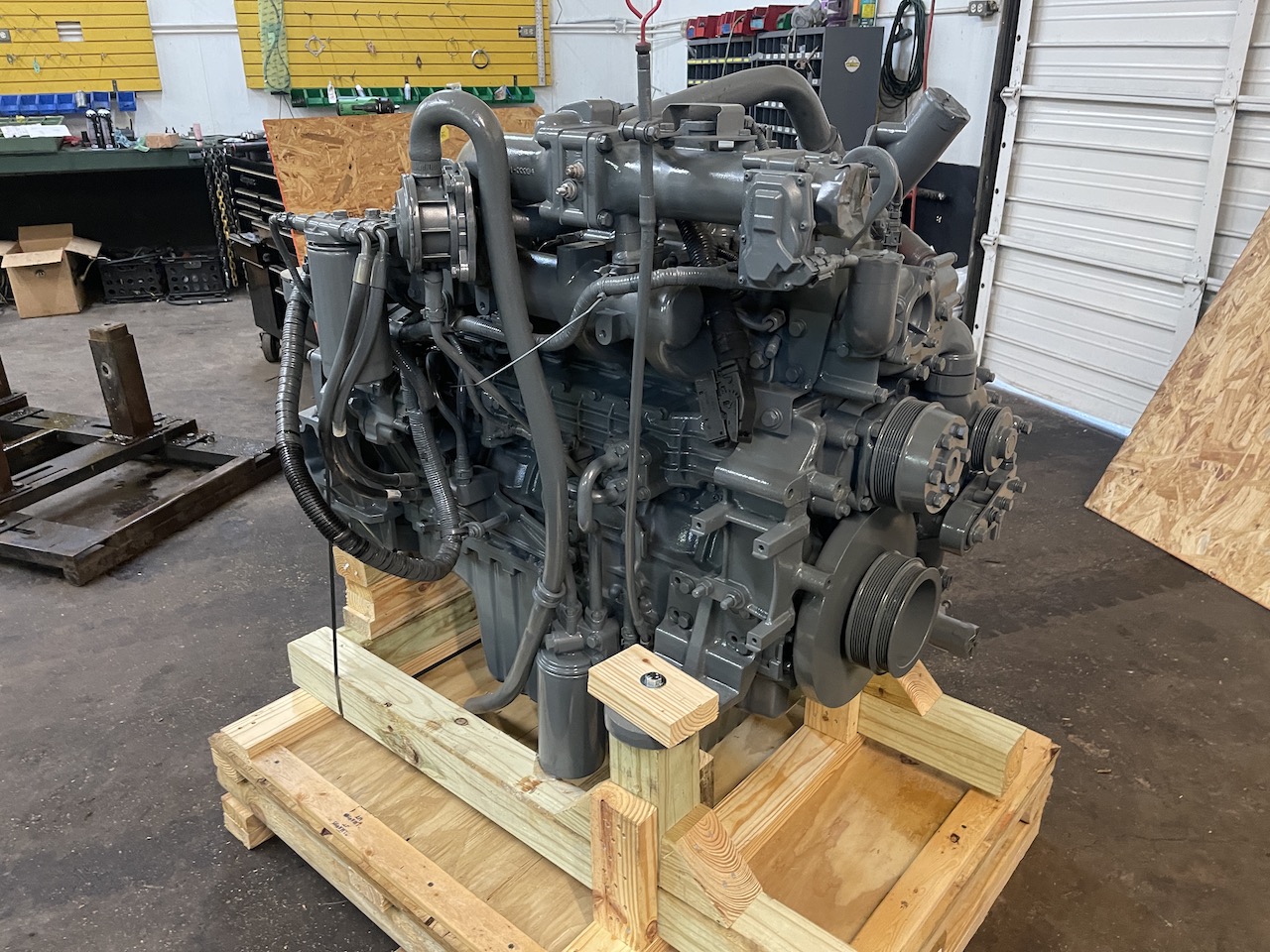

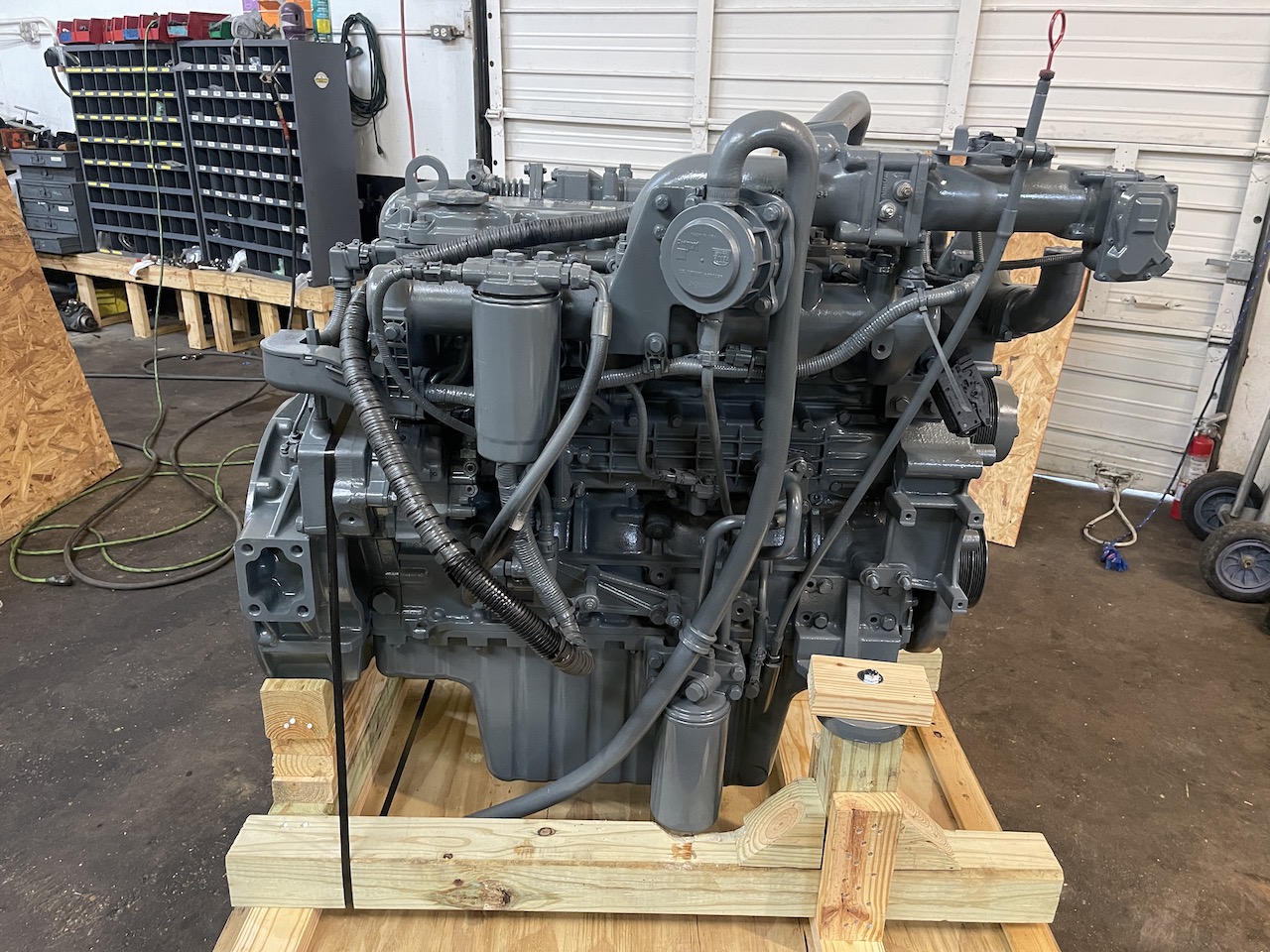

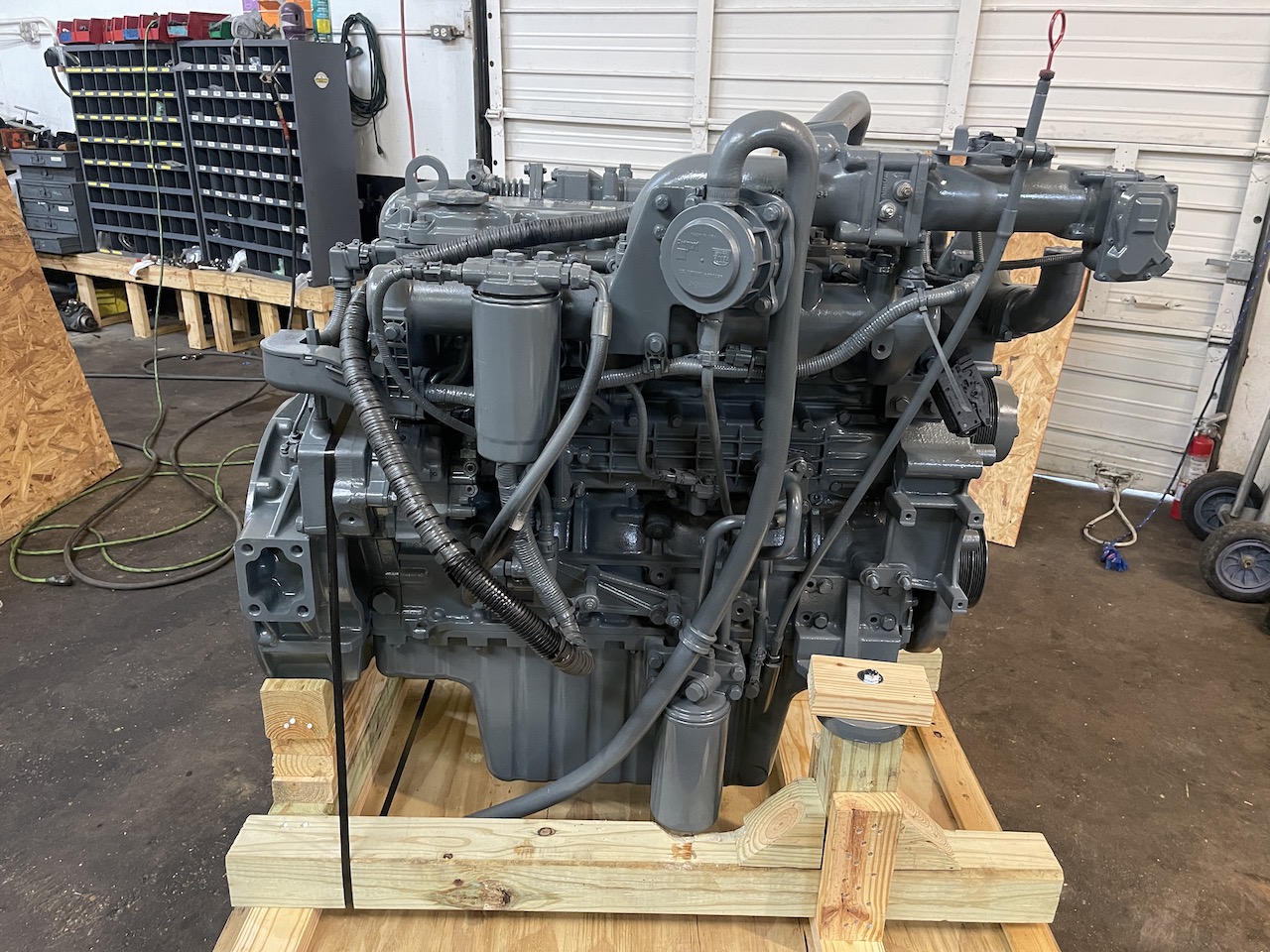

Examples of diesel engine shipping stands,

We hope you found this article helpful. If you have any questions or comments, please call us at 832-948-0975 or email sales@sheelysupply.com

![]()